Save Time

Earn More

Dry Faster

Fight Mold

Hemp Drying Quality vs Quantity

For the rapidly expanding hemp industry, Eco Logic Dry Kilns provide the vital link between harvesting and processing the full range of hemp products.

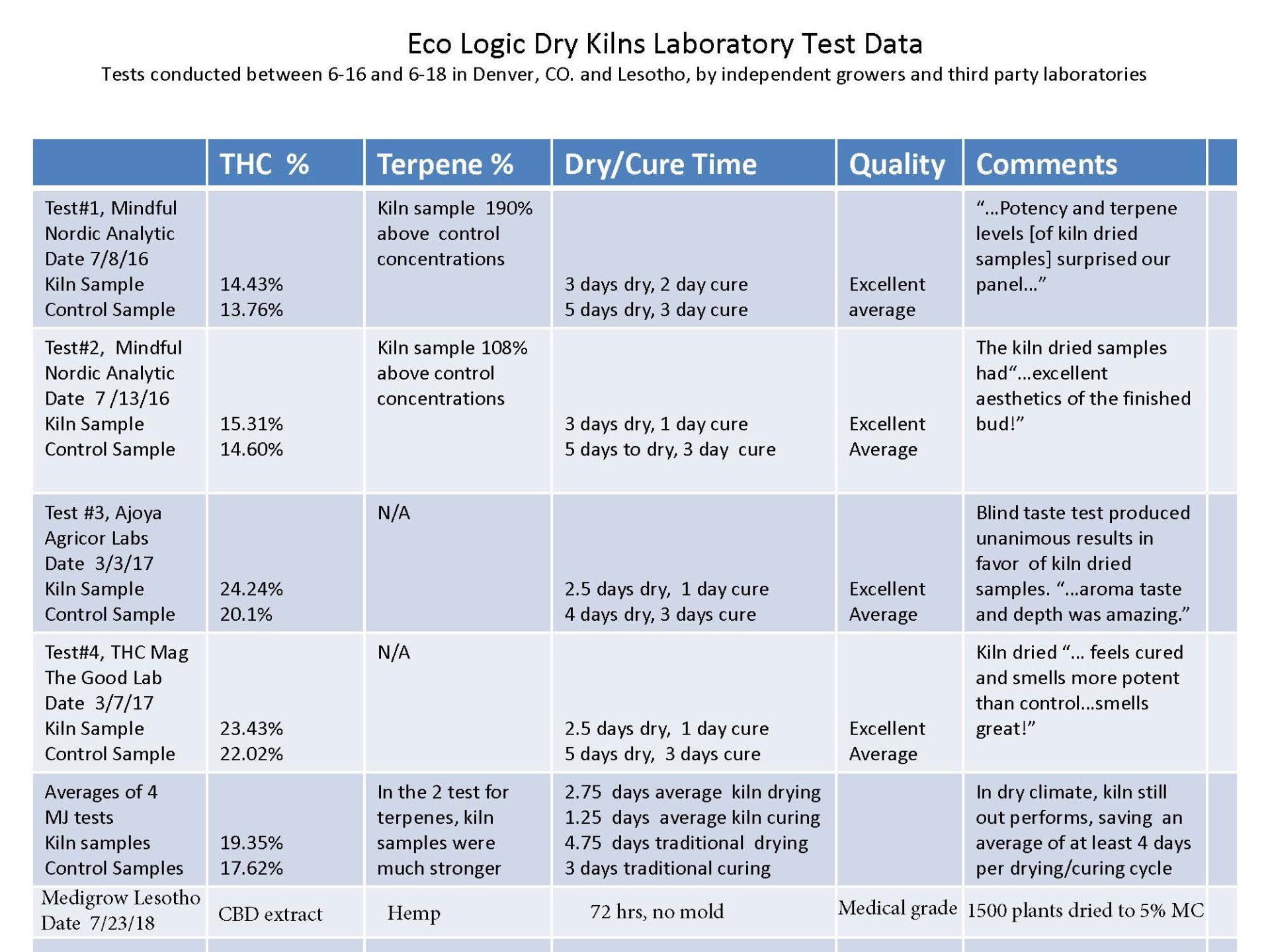

At a CBD production facility in Lesotho in Southern Africa, a medium sized Eco Logic Dry Kiln consistently dried 1500 hemp plants per cycle over a 5 month test period, producing high quality flower with no mold.

Complete control of the drying chamber environment means optimum temperature, humidity and air speed with no biological contamination, while reaching the target moisture content of your valuable crop.

Our patented Eco Walls extract moisture without energy expenditure, greatly reducing total energy requirements. These walls are combined with an Underwriters Laboratory Certified control system providing target heat, humidity and air flow.

Third party testing has consistently proven Eco Logic Dry Kiln's industrial scale drying systems will gently and energy efficiently dry plant based agricultural products at scalable volume.

For greater volume production, Eco Logic Dry Kilns larger capacity chambers deliver top quality without damaging fragile trichomes and terpenes.

If drying tons of biomass per hour fits your production goals, there are companies offering tons per hour of drying capacity.

We offer something different; the best possible drying environment for your valuable crop.

Our patented Eco Walls allow the less desirable chlorophyll in the hemp to break down while allowing the full spectrum of beneficial compounds in the fragile tricomes and terpenes to flourish.

Much less electrical power is required for the low speed circulation and exhaust fans, infrared emitters, monitoring and controls. In hot and humid climates, air conditioning may also be required.

Comparison with the competition

Large hemp biomass yields fetch much lower commodity prices of $25 to $50 per pound, whereas quality dried flower can reach $300 to $600 per pound, based on the US 2019 harvest.

Although there is great variation in plant size at harvest, our production estimates are based on assigning a base number of one pound of dried hemp flower per plant and 3 cubic feet of volume per plant in the drying chamber.

Our larger capacity kilns can hold from 3000 to 9,600 hemp plants per drying cycle, per unit. With an average estimated 1500 plants harvested per acre, one larger ELDK dry kiln can dry 2 to 5 acres per cycle. With staggered harvesting, large acreage harvests can be dried with maximum full spectrum results, without loss to mold. Drying times at high volume range from three to six days.

Eco Logic Dry Kilns designs can also include mobile drying chambers, rolling carts and/or racks, floor plan suggestions for containment buildings, material flow diagrams, power input, AC and venting.

We look forward to developing the best designs for your hemp drying needs!

.